The Benefits of Thermoelectric Chillers as compared to compressor chillers

Thermoelectric recirculating chillers (also called Peltier chillers) have many benefits and advantages when compared to compressor-based chillers. Thermoelectric chillers utilize multiple arrays of thermoelectric chips (TECs) coupled with heat sinks, fans and liquid heat exchangers to provide extremely accurate thermal control of the outgoing fluid. As TECs also have the ability to heat as well as cool, thermoelectric chillers provide extremely fast and accurate temperature control and stability and can reach a temperature stability of just a few 0.01°C with a stable heat load. Compressor chillers utilize compressors with refrigerant, condensers and evaporators to provide bulk cooling and typically resistive heaters in order to counteract the on-off cooling of compressors.

Thermoelectric recirculating chillers (also called Peltier chillers) have many benefits and advantages when compared to compressor-based chillers. Thermoelectric chillers utilize multiple arrays of thermoelectric chips (TECs) coupled with heat sinks, fans and liquid heat exchangers to provide extremely accurate thermal control of the outgoing fluid. As TECs also have the ability to heat as well as cool, thermoelectric chillers provide extremely fast and accurate temperature control and stability and can reach a temperature stability of just a few 0.01°C with a stable heat load. Compressor chillers utilize compressors with refrigerant, condensers and evaporators to provide bulk cooling and typically resistive heaters in order to counteract the on-off cooling of compressors.

The solid-state nature of the TEC (no moving parts) leads to a very high reliability for the entire thermoelectric chiller system. There are no consumables, or refrigerant required ever. Additional as there is no compressor used, the vibration for a thermoelectric chiller is extremely minimal and much smaller than that of a compressor chiller.

Size and noise are other important distinctions. Thermoelectric chillers are typically lighter and smaller than comparative sized compressor-based chillers and are typically quieter as well.

This fundamental difference gives solid-state thermoelectric coolers the following advantages over other methods of cooling:

- They allow for very tight and accurate temperature control

- No moving parts. Therefore they require little or no maintenance. Ideal for cooling parts that may be sensitive to mechanical vibration.

- No refrigerants, such as potentially harmful CFCs. Therefore environmental and safety benefits.

- Enables reduced, low-noise operation of cooling fans, while providing greater cooling power.

- Allow for systems to be lightweight and compact due to their small size.

- Long life. The solid state nature of TECs Exceeds 100,000 hrs MTBF (Mean Time Between Failures).

- Fast, dynamic response.

Principle of Thermoelectric Operation

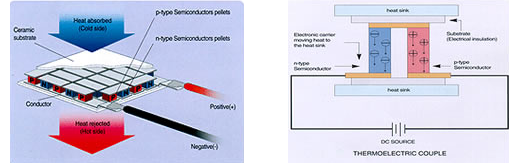

Thermoelectric coolers (TECs), also known as Peltier coolers, are solid-state heat pumps that utilize the Peltier effect to move heat. Passing a current though a TEC transfers heat from one side to the other, typically producing a heat differential of around 40°C—or as much as 70°C in high-end devices—that can be used to transfer heat from one place to another.

The principle of thermoelectric cooling dates back to the discovery of the Peltier Effect by Jean Peltier in 1834. All electric current is accompanied by heat current (Joule heating). What Peltier observed was that when electric current passed across the junction of two dissimilar conductors (a thermocouple) there was a heating effect that could not be explained by Joule heating alone. In fact, depending on the direction of the current, the overall effect could be either heating or cooling. This effect can be harnessed to transfer heat, creating a heater or a cooler.

When two conductors are placed in electric contact, electrons flow out of the one in which the electrons are less bound, into the one where the electrons are more bound. Current passing across the junction results in either a forward or reverse bias, resulting in a temperature gradient; Cold vs. Heat! If the temperature of the hotter junction (heat sink) is kept low by removing the generated heat, the temperature of the cold plate can be cooled by tens of degrees.

In practice many TEC pairs (or couples) are connected side-by-side, and sandwiched between two ceramic plates, in a single TEC unit.